Product Description

MAIN APPLICATION

The quality dry granulator machine For sale is a new piece of equipment that uses the crystalline water in the material to directly make the powder into granules. The machine has a novel and reasonable structure, stable and reliable performance, and convenient cleaning and maintenance. The granules made by the machine can press tablets. Make a powder. Irrigation capsules, etc. The machine is mainly used for granulation in pharmaceutical, food, chemical, and other industries. It is especially suitable for granulation of materials that cannot be solved by wet methods.

It adopts a dry granulation process, which avoids the use of liquid binders, reduces moisture during the granulation process, and helps improve the stability of the finished product and extend its shelf life. Secondly, since there is no need to add moisture, this granulator can reduce stickiness and viscosity problems in the process and ensure the uniformity and flowability of the product.

Quality dry granulator products For sale are usually easy to operate and maintain, reducing production costs. Its granulation process can achieve precise control of particle size by adjusting parameters to meet the needs of different product specifications. Since no drying step is required, time and energy are saved and production efficiency is improved.

Peixin series dry granulator is mainly composed of feeding system, reversing feeding system, extrusion system, crushing system, front cover system, water cooling system, granulation system, hydraulic system and rotary screen control system. The whole body includes the inner part and the outer part. All drive parts and ancillary facilities are designed inside the machine body. Working part in contact with materials are set outside the operation panel which is isolated by multiple sealing parts in the middle. The working parts will work in a completely sealed parts in contact with materials can be easily disassembled and cleanpd, which can effectively prevent dust leakage and avoid the possibility of pollution Therefore, it can meet requirements of production GMP.

TECHNICAL PARRAMERTERS

| Model Model |

Production capacity (kg/h). |

Production Size (mm). |

Working Pressure (kn) |

Motor Power (kW) |

Overall Dimension (L*W*H) (mm) |

Weight (kg) |

| GK-70 type | 20-100 | 0.5-3 | 198 | 11.1 | 1600*1000*2230 | 2000 |

| GK-100 type | 50-150 | 0.5-3 | 297 | 11.8 | 1560*1000*2230 | 2200 |

| GK-120 type | 60-200 | 0.5-3 | 69° | 13.8 | 1560*1000*2230 | 2500 |

| GK-200 type | 80-300 | 0.5-3 | 310 | 25 | 2150*1250*2700 | 3500 |

Product Application

Dry granulators are widely used in health care products, chemical industry, food and other fields, and are mainly used to prepare granular raw materials, fertilizers, catalysts and other substances. Among them, in the health care products industry, dry granulator is one of the main equipment for preparing solid preparations. Through this equipment, powdery or granular raw materials and auxiliary materials can be mixed and pressed into particles of various prescribed shapes and sizes. In the chemical and food industries, the equipment is also capable of preparing a variety of granular products.

GK series dry granulator

The machine is a new equipment that uses the crystalline water in the material to directly make powder into granules. The machine has novel and reasonable structure, stable and reliable performance, and convenient cleaning and maintenance. The granules made by the machine can press tablets. Make a powder. Irrigation capsules, etc. The machine is mainly used for granulation in pharmaceutical, food, chemical and other industries. It is especially suitable for granulation of materials that cannot be solved by wet methods.

Get in touch for more information or to arrange a demo:

Products Category

Product Description

MAIN APPLICATION

The quality dry granulator machine For sale is a new piece of equipment that uses the crystalline water in the material to directly make the powder into granules. The machine has a novel and reasonable structure, stable and reliable performance, and convenient cleaning and maintenance. The granules made by the machine can press tablets. Make a powder. Irrigation capsules, etc. The machine is mainly used for granulation in pharmaceutical, food, chemical, and other industries. It is especially suitable for granulation of materials that cannot be solved by wet methods.

It adopts a dry granulation process, which avoids the use of liquid binders, reduces moisture during the granulation process, and helps improve the stability of the finished product and extend its shelf life. Secondly, since there is no need to add moisture, this granulator can reduce stickiness and viscosity problems in the process and ensure the uniformity and flowability of the product.

Quality dry granulator products For sale are usually easy to operate and maintain, reducing production costs. Its granulation process can achieve precise control of particle size by adjusting parameters to meet the needs of different product specifications. Since no drying step is required, time and energy are saved and production efficiency is improved.

Peixin series dry granulator is mainly composed of feeding system, reversing feeding system, extrusion system, crushing system, front cover system, water cooling system, granulation system, hydraulic system and rotary screen control system. The whole body includes the inner part and the outer part. All drive parts and ancillary facilities are designed inside the machine body. Working part in contact with materials are set outside the operation panel which is isolated by multiple sealing parts in the middle. The working parts will work in a completely sealed parts in contact with materials can be easily disassembled and cleanpd, which can effectively prevent dust leakage and avoid the possibility of pollution Therefore, it can meet requirements of production GMP.

TECHNICAL PARRAMERTERS

| Model Model |

Production capacity (kg/h). |

Production Size (mm). |

Working Pressure (kn) |

Motor Power (kW) |

Overall Dimension (L*W*H) (mm) |

Weight (kg) |

| GK-70 type | 20-100 | 0.5-3 | 198 | 11.1 | 1600*1000*2230 | 2000 |

| GK-100 type | 50-150 | 0.5-3 | 297 | 11.8 | 1560*1000*2230 | 2200 |

| GK-120 type | 60-200 | 0.5-3 | 69° | 13.8 | 1560*1000*2230 | 2500 |

| GK-200 type | 80-300 | 0.5-3 | 310 | 25 | 2150*1250*2700 | 3500 |

Product Application

Dry granulators are widely used in health care products, chemical industry, food and other fields, and are mainly used to prepare granular raw materials, fertilizers, catalysts and other substances. Among them, in the health care products industry, dry granulator is one of the main equipment for preparing solid preparations. Through this equipment, powdery or granular raw materials and auxiliary materials can be mixed and pressed into particles of various prescribed shapes and sizes. In the chemical and food industries, the equipment is also capable of preparing a variety of granular products.

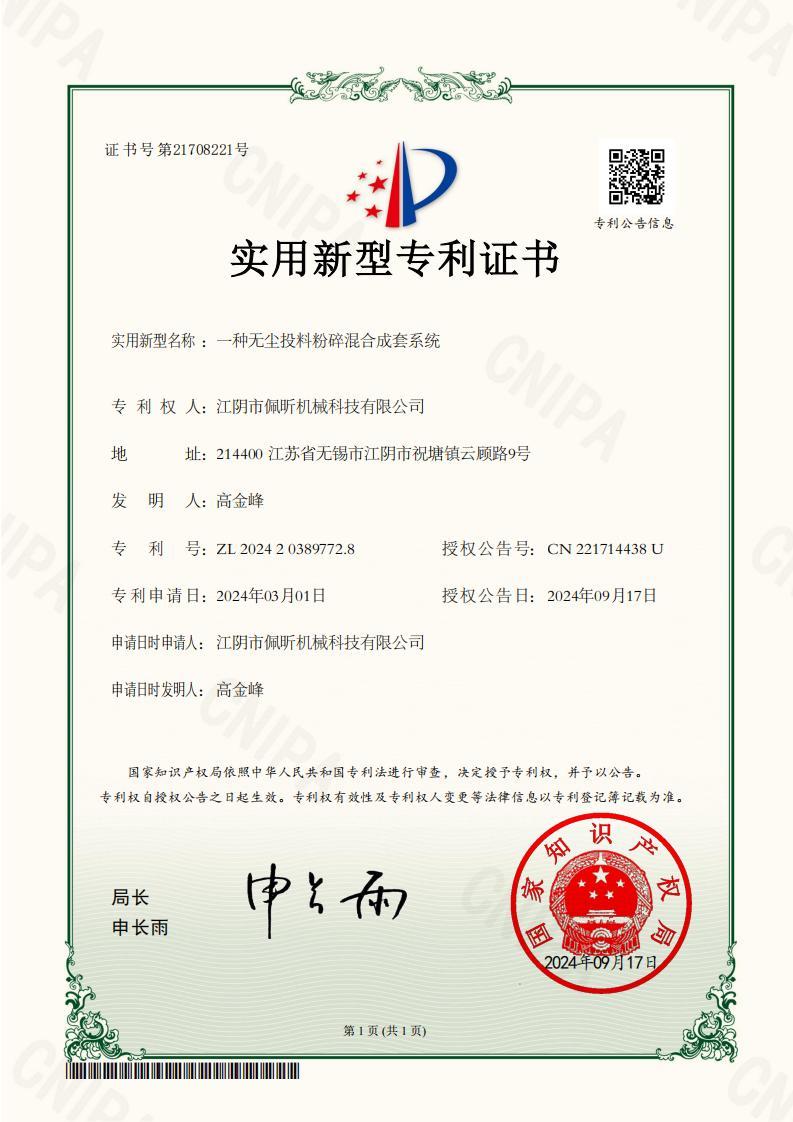

说明页内容……

WHO IS PEIXIN?

Jiangyin Peixin Machinery Technology Co.,Ltd has 15 year experences in Powder Processing Equipment. The company is a comprehensive production enterprise that integrates equipment technology R &D, production, sales, and after-sales service. It specializes in producing high-performance ultrafine grinder and related mechanical equipment. As a specialized production enterprise in the field of powder technology, Peixin Machinery has established a high status and reputation in the powder industry through years of technological accumulation and research and development production advantages.

Contact Us

Fill all information details to consult with us we will be happy to help you!

Customer Visit

FAQ

How about your payment term?

1. Normally we can work on T/T or L/C.

2. On T/T term, 30% down payment is required in advanced. And 70% balance shall be settled before shipment.

3. On L/C term, a 100% irrevocable L/C without soft clause can be accepted. Please seek the advice from the individual sales manager whom you work with.

4. Video / CD of test running and installation, Maunal book, tool box sent with machine

What's your shipping item process?

We have long-term working shipping forwarder. We can do our best to send machine to your port safe and sound.

If your need, we can help you do custom clearance.

Packaging Details:

1. Outside package: Standard export wooden cases.

2. Inner package: Stretch film.

Delivery Details: Machine will be finished in about 25 workdays after payment.

What's your before & after service

1) Professional advice and rich experience help to choose machine.

2) Longtime maintainance and considerate technical support

3) Technicians can be sent to abroad to install.

4) ONE year guarantee. WHOLE life service. Within1 year, any problem part can send to us, we can give provide free new part(only damaged by machine itself).

5) Any problem before or after delivery, you could find and talk with us anytime. We will free supply technical support.

6) Video / CD of test running and installation, Maunal book, tool box sent with machine if client request.

How to visit your company

Our company is in WUXI city, near shanghai cisty, only 20mins away from WUXI EAST TRAIN STATION. Or you can call us anytime you arrive Wuxi, i will go to pick you.

Can you give me guide on other machine To full my production line

YES ! Our company has a long history, we also can recommend you other machine supplier which we don't sale, like packing machine, filling machine, etc !!

What machine your company have can customized machine upon my needs

Yes, we also produce CRUSHER, GRINDER, MIXER, DRYER, GRANULATOR, VIBRATING SIFTER, CONVEYOR, etc.

We absolutely can customized machine upon your side, just freely tell me your needs or design request, i will check and give you quotation.

Are you real factory or trading company

YES ! We are real and most reliable factory here. Welcome you visit us anytime! After compare, you will know we are most expert and big factory here!!

Get Product Information For Free

Note: Please leave your email address, our professionals will contact you as soon as possible!